Add to Cart

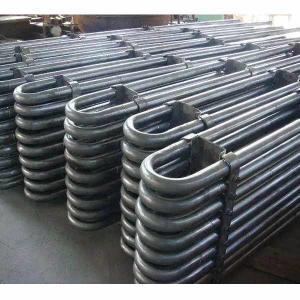

Factory Supply Good Quality Tube Coil Heat Exchanger

Description

The coil type heat exchanger is made of anti-corrosion materials, and the finished product is not affected by environmental factors and pipeline medium composition. Through professional welding, it has the effects of good corrosion resistance, low thermal conductivity, insulation and energy saving. Extending the service life of the heat exchanger can bring benefits to customers.

Specifications

| Model | 010CA | 015CA | 020CA |

| Heat exchanger power | 10HP | 15HP | 20HP |

| Cooling capacity | 35kw | 52.5KW | 70KW |

| Heating capacity | 50kw | 75KW | 100 |

| Media inlet diameter(mm) | 25 copper | 25 | 25 |

| Media outlet diameter(mm) | 32 copper | 32 | 38 |

| Tube material | Stainless steel 304 | Stainless steel 304 | Stainless steel 304 |

| Tube diameter*thickness*length(mm) | 19*0.7*40000 | 19*0.7*60000 | 19*0.7*80000 |

| Diameter K(mm) | 300 | 350 | 400 |

| Dimension L(mm) | 250 | 300 | 350 |

| Diameter M(mm) | 200 | 250 | 300 |

| Diameter N(mm) | 150 | 200 | 250 |

| Weight (kg) | 18kg | 22kg | 28kg |

Structural features:

1. The coil-type heat exchanger uses seamless steel pipe as the outer pipe for conveying fluid, and bends it together with the copper tube bundle that goes through it to form a casing body in a stacked spiral shape. It is welded and consolidated, and the two ends of the sleeve are respectively led out of refrigerant and cooling water to connect the waterway.

2. The two ends of the tube bundle of the heat exchanger are respectively connected to the liquid separator and the collecting cavity tube, which effectively promotes the equal amount of refrigerant to enter and exit, realizes rapid distribution and aggregation, and makes full use of the heat exchange efficiency of each tube.